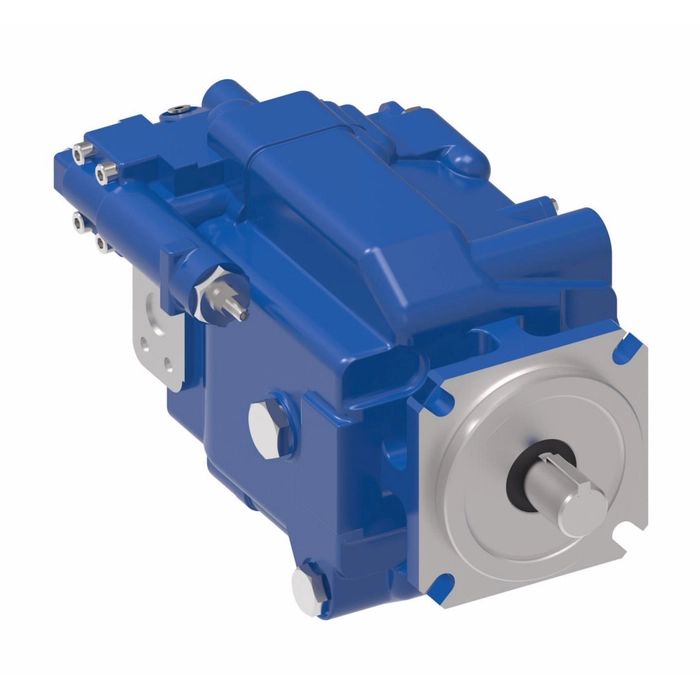

5 Features of Vickers VQA2 vane pumps

Vickers VQA2 vane pumps are compact, high-efficiency positive-displacement pumps that are ideal for the transfer of viscous fluids. The VQA2 series is available in vertical and horizontal configurations and offers flow rates ranging from 2 to 250 GPM (gallons per minute).

The pump’s unique design provides a wide range of capabilities including heating, cooling, mixing, blending and conveying applications. The VQA2 is also well suited for applications requiring very low pressure drops such as those found in chemical handling applications.

Here are five features that make the VQA2 a great choice for your application:

The Vickers VQA2 vane pumps have a modular design.

The Vickers VQA2 vane pump is a modular packaged pump for use in a wide range of applications.

The Vickers VQA2 vane pump has a modular design. The unique modular design allows the maximum performance from the smallest package size and low cost. The VQA2 series is available in one, two, three and four stage configurations with flow rates from 0.05 to 3 gallons per minute (0.14 to 11 liters per minute).

The Vicker’s VQA2 series pumps are manufactured for long life and dependability with easy serviceability. They are ideal for use in many industrial applications including automotive, chemical, food processing, pharmaceutical and water treatment systems as well as many other uses where precise pumping requirements call for high efficiency at low cost per horsepower hour or kW/h.

The VQA2 is designed to provide small displacement and high pressures.

The VQA2 pumps are compact, lightweight, high-performance centrifugal pumps with a compact body and rotor design for applications requiring small displacement and high pressures. The VQA2 pumps are available as a single-stage centrifugal pump or as a two-stage centrifugal pump with a separate booster pump.

The VQA2 family of pumps is ideal for use in water treatment plants, chemical plants, petroleum refineries and other industrial applications where reliable operation at high pressure and low flow rates is required.

Vickers Pumps offers several models of VQA2 two-stage centrifugal pumps in sizes ranging from 1/4″ to 2″ (DN 6 to DN 50). Each model has flow rates up to 22 gpm (0.8 m3/h) at pressures up to 3200 psi (218 bar). All models are capable of operating at temperatures up to 200 F (93 C).

The Vickers VQA2 vane pump can be operated in either the clockwise or counter-clockwise direction.

Vickers VQA2 vane pumps are designed to operate with a maximum speed of 2,500 rpm and provide pressure ratings to 500 psi (3.45 MPa). The design includes a pre-lubricated bronze-bronze bearing system that extends the life of the pump. They also feature a full flow design for maximum performance in applications such as sewage treatment plants, industrial cooling towers, heat exchangers and other process applications.

The Vickers VQA2 vane pump can be operated in either the clockwise or counter-clockwise direction. The pump has been designed to handle a wide variety of fluids and gases, including high temperature liquids such as water, oil and gasoline. This pump is compact and lightweight, making it ideal for use on portable equipment or smaller application where space is limited.

Vickers Pumps are manufactured according to international quality standards and are available in a variety of materials including cast iron, cast aluminum and brass with stainless steel shafts. All Vickers Pumps meet or exceed ANSI B72 requirements (except for double suction pumps) and are UL listed through Underwriters Laboratories (UL).

The VQA2 can be configured for low noise operation.

The VQA2 is a compact, high performance vane pump which can be configured for low noise operation. The VQA2 is available in both single and double stage configurations, with maximum flow rates up to 7 L/min.

The pump operates at low speeds (10-15 rpm) with a typical pumping head of 1.8 m. Pumping heads up to 4.5 m are available on request. The VQA2 uses double acting cylinders which allow the pump to operate in either direction without reversing the motor.

The VQA2 has been designed with an emphasis on performance and reliability under extreme conditions, including high temperature and pressure as well as vibration resistance. The pump has also been designed to withstand prolonged exposure to aggressive fluids without any significant loss of performance or efficiency due to corrosion or erosion caused by these fluids.

The Vickers VQA2 pumps is supported by a wide range of accessories, including manual shut-off valves, reservoir and pressure relief valves.

In addition to the standard range of operating pressures up to 135 bar (2,000 psi), Vickers Pumps offers a high-pressure version of the VQA2 that can deliver up to 200 bar (3,000 psi). This high-pressure pump can be used in applications such as firefighting pumps or hydraulic jacks on heavy vehicles.

The VQA2 is available in 2-, 3- and 4-stage configurations with single or double suction designs. The double suction design allows for higher flow rates at low pressures compared to other single suction pumps.

The VQA2 has been tested for reliability and durability under severe conditions in many applications around the world. It has proven itself as an excellent choice for power steering systems on earth moving equipment such as loaders and excavators where it provides reliable performance without maintenance for many years without problems.

Make sure your hydraulics are up to snuff with the latest offerings from Eaton.

Eaton’s latest product line of VQA2 vane pumps is designed to provide the highest level of performance and reliability. The new VQA2 vane pump is a high-flow, high-pressure hydraulic pump that is compatible with a variety of applications.

The new VQA2 vane pump can be used in a wide range of applications including construction, industrial manufacturing and material handling. It can also be used in several different industries including mining and agriculture.

The new Eaton VQA2 vane pumps are available in capacities ranging from 100 to 600 horsepower (75 to 450 kW). This gives customers plenty of options when it comes to selecting the right model for their application needs.

Each model features an integral gearbox design that reduces maintenance requirements by simplifying service tasks and increasing efficiency. Additionally, all components are completely enclosed for added protection against dust, dirt and debris buildup which may affect performance over time.

In a nutshell, Vickers is a world leader in the design and manufacture of industrial pumps and motors. Its focus on engineering excellence goes right to the heart of its products, with reliability and long-lasting performance, as well as dependable customer service also forming part of its core business ethos.