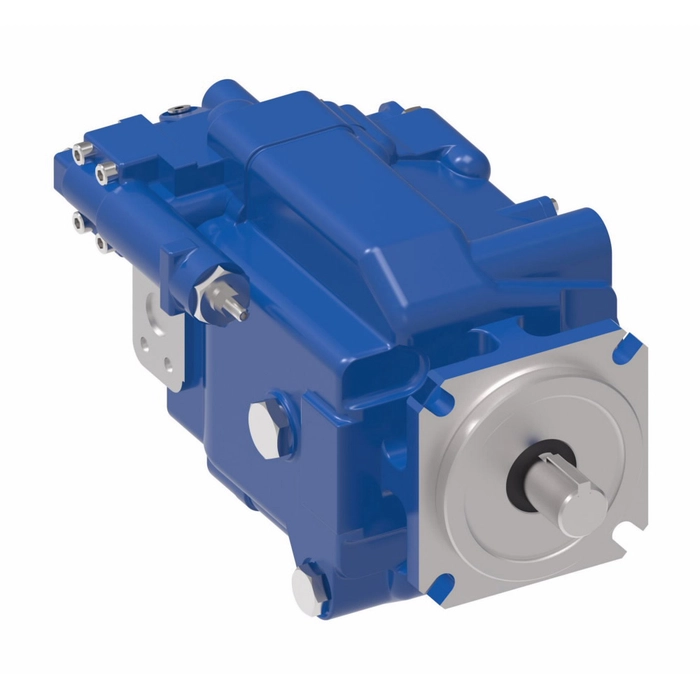

Vickers PPOC-M Series Piston Pumps- New Optimized Features

The Vickers PPOC-M Series Piston Pumps are designed to meet the requirements of a variety of industrial applications including chemical processing, petrochemical, and power generation. The compact design, superior performance and long life of these pumps make them an ideal solution for any application that requires high flow rates at low pressure levels.

Hydraulic customers, who operate in the open loop, have often had to choose between the relatively high efficiency of piston pumps, and their low noise characteristics.

The PPOC-M Series of pumps has been designed to provide a solution to this problem. These pumps are designed to be installed in open loop applications where the pump is exposed to high temperatures and/or pressures.

The PPOC-M Series of pumps can be used in applications such as air conditioning systems and heat exchangers. The pumps are designed to withstand temperatures up to 150°C with pressure up to 15 bar (200 psi). The compact design makes these pumps ideal for use in confined spaces.

The Vickers PPOC-M Series Piston Pumps are designed to provide a much wider operating speed range than previous models.

The latest addition to the Vickers PPOC series of high pressure centrifugal pumps, the PPOC-M pump has been designed to provide a much wider operating speed range than previous models. The design allows operation over a wide range of speeds from 80 rpm to 2,000 rpm and can be used in applications ranging from water treatment plants, cooling towers and process industries to power generation and marine propulsion systems.

The PPOC-M piston pump is available in four different sizes with hydraulic characteristics that allow it to be used as an open or closed loop pump. The pumps are available with NACE MR0175 compliance and are also suitable for use in applications where flammable gases may be present.

The PPOC-M piston pumps are based on proven Vickers technology which offers high efficiency levels while providing reliable operation without maintenance over long periods of time. A key feature of the design is its ability to operate at low pressures with low torque requirements which helps reduce wear on shafts and bearings compared with other types of centrifugal pumps.

These energy efficient pumps have newly designed features to optimize performance and reduce noise.

Vickers’ PPOC-M series pumps are designed for high efficiency, low vibration and quiet operation. The pumps are available in several different configurations with a variety of flow rates and pressure ratings to meet a wide range of applications.

The new M series piston pump is designed for use with a wide variety of fluids including water, oil or other non-corrosive liquids. The new design features an integrally cast housing that eliminates welds, which means there is no chance for leaks or corrosion. This design also allows the motor and pump to be installed as one piece, which reduces installation time and cost while increasing reliability due to fewer potential leak points during assembly.

The new PPOC-M Series is designed to increase productivity and lower operational costs.

The PPOC-M Series offers both high pressure and high flow rates, as well as low noise levels. The small footprint of the pump allows for easy integration into existing systems.

The Vickers PPOC-M Series offers a narrow design which produces less noise and vibration than other pumps in the same class, making them ideal for use in noisy environments such as factories, refineries and offshore rigs. The pump will fit inside a standard Nema 4X enclosure, making it ideal for harsh industrial environments where maintenance access is limited.

The PPOC-M Series uses an oil lubricated piston rod pump design, which does not require any serviceable parts such as O-rings or seals that could fail over time leading to expensive downtime or even loss of product. This also eliminates the need for frequent lubrication of the system with potentially dangerous hydraulic fluids. With no moving parts inside the pump housing, there is no chance of contamination from foreign matter entering the system while it is running: another benefit in an industrial environment where product contamination must be avoided at all costs.

New sealing technology reduces noise levels and improves service life.

The Vickers PPOC-M Series piston pumps are designed for use in high pressure applications where low vibration and easy maintenance are required. The pump is ideal for circulating liquids or gases in industrial processes such as chemical, petrochemical and power generation plants.

The PPOC-M Series is available with one or two stages of pumping, with a wide range of capacities from 3 to 200L/min (0.1 to 7.1gpm) at pressures up to 100 bar (1400 psi). The design incorporates a seal system that reduces noise levels by up to 50% compared with previous models, while reducing wear on moving parts by 20%.

New pressure balanced flange and shaft seal design provides greater protection from contamination and reduces leakage.

The Vickers PPOC-M Series Piston Pumps are designed for high pressure, medium flow applications with a maximum operating pressure of 600 PSI (41 Bar). These pumps are available with a single or double acting piston design, with an optional key start motor that is designed for continuous duty. The new pressure balanced flange and shaft seal design provides greater protection from contamination and reduces leakage. This pump comes complete with all necessary mounting hardware; including a standard NEMA 4X enclosure.

Reduced flow pulsation technology results in quieter operation.

The VPPOC-M Series has been developed for continuous duty applications, such as water supply and wastewater treatment plants, food and beverage processing plants, chemical plants and others. The pump is available in two models; the PPOC-M series with a maximum flow of 1,000 GPM at a head of 100 feet and the PPOC-L series with a maximum flow of 2,500 GPM at a head of 50 feet. Both models are available in both single and three phase configurations.

The VPPOC-M Series uses a unique piston design that provides superior performance over traditional designs. This design provides reduced flow pulsation and lower noise levels than comparable pumps. The low pulsation level makes these pumps ideal for use in sensitive environments such as hospitals or hotels where quiet operation is required. The pump also features a high efficiency impeller that reduces heat generation when operating at full capacity. This improves motor life by reducing motor temperature rise so less frequent motor replacement may be necessary over time if properly maintained.

The Vickers PPOC-M Series Pumps are optimized for open loop applications.

The PPOC-M Series is a high performance pump designed for use in open loop applications, such as oil and gas production, where the fluid being pumped is either corrosive or has a high viscosity.

The pumps feature a self-priming design and Vickers’ patented diaphragm seal design to prevent internal leakage while maintaining high reliability at high temperatures and pressures.

If you need a new piston pump, or if you are adding a pump to your fleet, Vickers PPOC-M Series Piston Pumps offer superior metering accuracy, increased capabilities and better overall performance than other pumps of their kind. For more information about any of the models found in this article or to learn about the other products in the Vickers line, please get in touch with us .