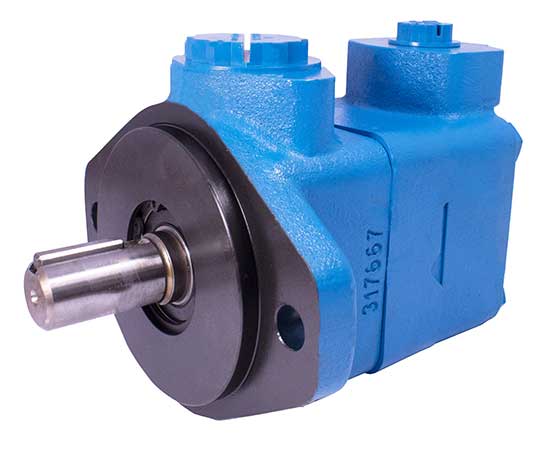

Characteristics of Vickers VQA1 vane pumps

Vickers VQA1 vanes pumps are designed to be used in a variety of applications, including marine, chemical and pharmaceutical industries. These pumps are known for their reliability and durability. They can also withstand high pressure as well as high temperatures. They are ideal for pumping liquids that have high viscosity or abrasive qualities.

The following are some of the characteristics of Vickers VQA1 vane pump:

Vickers VQA1 vane pumps is a fixed displacement pump.

The Vickers VQA1 vane pumps are designed for use in air conditioning and refrigeration systems. They are available in a variety of capacities and flow ratings, from 1/8 HP to 10 HP and from 1 GPM to 25 GPM. The VQA1 vane pumps are suitable for use with refrigerants R-22, R-134a and R-410A. The VQA1 vane pump can be used for systems that require more than one stage of cooling or heating. The VQA1 has been designed for easy installation, operation and maintenance, with minimum service requirements.

The VQA1 vane pump features sealed bearings, which provide long life with low maintenance requirements due to their self lubricating design. This feature also helps prevent contamination of the system by keeping dirt out of the pump’s bearings during operation. In addition, it provides protection against leakage due to corrosion because it is an integral part of the shaft seal assembly rather than an external component attached by means of a bolt or nut connection that could loosen or become loose over time resulting in leakage into the system if not properly tightened after each use or check

Vickers VQA1 vane pumps has simple, strong structure.

Vickers VQA1 vane pumps has simple, strong structure. Its parts and components are all made of high-quality materials, ensuring its long service life. The pump is easy to operate and maintain. It is widely used in petroleum, chemical and other industries in the process of oil refining, storage and transportation.

The Vickers VQA1 vane pump is a kind of rotary positive displacement pump which uses a belt-driven centrifugal impeller to pressurize the fluid through a discharge port using mechanical force. It works on the principle of the rotating impeller pressurizing a chamber behind it by changing the direction of flow and increasing its speed.

Vickers VQA1 vane pumps are easy to install and maintain.

Vickers VQA1 vane pumps are used in a variety of applications. These pumps are used in agriculture, construction, mining and other industries. The pump can handle dirty water and oil that other pumps cannot. It can also handle high pressure levels that other pumps cannot handle.

The Vickers VQA1 vane pump is a centrifugal pump with an internal rotor shaft that has vanes attached to it. The vanes spin at high speed when the motor spins the shaft. This causes the vanes to move liquid through them as they spin.

There are many different models of Vickers VQA1 vane pumps available today; however, they all have many things in common such as how they work, how they are installed and how they operate properly over time without wearing out quickly or breaking down unexpectedly.

The main areas of use of vane pumps is the hydraulic system with a small amount of flow and low pressure.

The pump is a rotary positive displacement pump, which is similar to a gear pump. It has a high compression ratio and high efficiency, but its flow rate is limited. The structure of this kind of pump can be divided into two kinds: one is a centrifugal pump; the other is an axial piston pump. Centrifugal pumps are mainly used in small-scale systems where high flow rates are required, while axial piston pumps are mainly used in large-scale systems where high pressures are required.

The design features of Vickers VQA1 pumps are designed for optimum operation at lower speeds. This reduces the noise level and increases stability and service life of the mechanical seal.

Vickers VQA1 vane pumps are available in a variety of sizes to suit your application, with capacities up to 40 GPM (150 LPM) at an efficiency range of 70% – 80%. These pumps can be driven by electric motors or by DC electric motors. The motor drives have integral overload protection and are suitable for use with either 115VAC/60Hz single phase or 230VAC/50Hz three phase power supplies. The discharge pressure is adjustable from 0 – 10 bar (0 – 150 psi).

The VQA1 series of vane pumps offer high pumping capacity at low speeds with a low noise level. These units are ideal for applications including:

Water supply systems in rural areas

Fire fighting systems in large buildings

Farm irrigation systems

The sealed bearing in the vane pump prevents rotation in the axial direction during engine shutdown.

The VQA1 is a single-stage, two-stage and turbocharged engine oil pump for automotive and industrial applications. It features a self-flushing design that allows for uninterrupted operation of the engine when used in vehicles with long oil drain intervals or severe duty cycle requirements. The VQA1 offers exceptional protection against wear, cavitation, corrosion and heat damage from exhaust gas recirculation (EGR) systems through its ability to maintain high flow rates at high temperatures. The VQA1 is designed to meet OEM specifications for rail pressure control, external leakage and reliability.

Each nozzle includes a pair of spring-loaded vanes that rotate in slots in the side wall.

The Vickers VQA1 vane pump is a positive displacement suction pump that has a maximum pressure of 15 bar. This pump is ideal for use in wastewater treatment plants and in the food, beverage and pharmaceutical industries.

The Vickers VQA1 vane pump features large diameter impellers and diffusers. Each nozzle includes a pair of spring-loaded vanes that rotate in slots in the side wall. The vanes are positioned so that they do not interfere with each other as they rotate around their axis. The spring-loaded design ensures that there is no metal-to-metal contact between the vanes and the casing during operation.

Vickers VQA1 vane pumps have been designed for use under high temperature conditions, with an operating temperature range of -20°C to +120°C / -4°F to +248°F. They can also be used in applications where aggressive chemicals may be present, such as caustic soda solutions or sodium hypochlorite solutions up to pH 12 (approximately equivalent to 12% sodium hypochlorite).

There are many important characteristics of this Vickers pump that distinguish it from other types ofl pumps.

The first is the simplicity of design. The heart of any centrifugal pump is its impeller, which consists of a number of blades mounted on a rotating shaft. As fluid enters through the inlet nozzles and exits through the discharge nozzle, centrifugal force causes the impeller to spin at high speed. This spinning motion forces fluid into and out of the pump casing through specially designed grooves or passages called volutes.

Overall the Vickers VQA1 is the best choice in this category. The low price and high quality make it a very good vane pump to use. It’s also a versatile pump that makes a good choice for vacuum or venturi applications, along with air pumping.