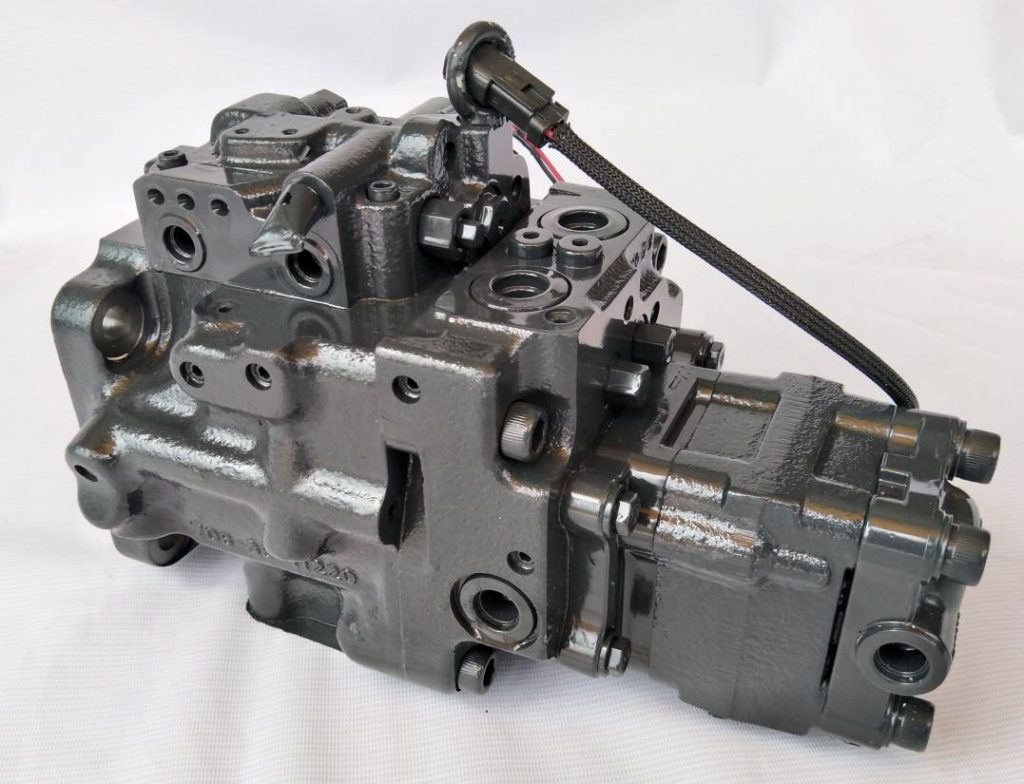

How to replace komatsu excavator hydraulic pump?

How to replace komatsu excavator hydraulic pump? When you are using a machine the most important thing is to check the machine regularly. You can do so by inspecting the machine yourself or get someone to help you with it. If you do not care enough about the working of your excavator and neglect it, some grievous damage may inevitably happen.

komatsu excavator hydraulic pump-Shut down the excavator, secure it, and release residual oil pressure in the system.

To begin troubleshooting, shut down the machine and perform a visual inspection of the hydraulic system to see if you can identify the source of the problem.

Next, isolate the source of your excavator’s issue by completing a thorough pressure test. If you notice leaks in any of your hoses, replace them immediately.

If you find that one of your excavator’s hydraulic cylinders is leaking, follow these steps to repair it:

Remove the bolts holding the cylinder in place and remove the cylinder from its mount. Then, remove the piston rod from its housing. Inspect both for damage and/or wear.

Replace any damaged components with new ones. Make sure to lubricate all parts prior to reassembly and installation.

Install all parts in reverse order of removal and test excavator for proper operation.

komatsu excavator hydraulic pump-Remove the cab and secure cab so that it’s out of harm’s way, but ready for installation.

If you’re removing a cab from an existing truck, the first step is to remove it. This may seem obvious, but it’s important that you do not rush this process for two reasons:

1. You will be replacing several structural components in the truck bed. If you rush through this process or damage any of these components, you could end up with a truck that has some serious safety issues.

2. Safety is important to us and we want our customers to feel safe driving their new trucks. Accidents can happen when you’re moving large objects, so take your time and make sure you have adequate help on hand to get the job done safely.

We recommend having at least two people during this process: one person to hold the cab while another person disconnects all of the electrical components and removes it from the truck frame.

Remove the cab and secure cab so that it’s out of harm’s way, but ready for installation.

komatsu excavator hydraulic pump-Remove the hydraulic tank, engine hood and pump mount.

Remove the hydraulic tank, engine hood and pump mount. This will give you access to the drive shaft and gearbox.

Unbolt the PTO shaft from the gearbox (Photo 1). You may need to use a wrench or socket to hold the shaft in place while you turn the nut with another wrench or ratchet. Remove the PTO shaft from the gearbox.

Remove any belts that are attached to the gearbox pulley (Photo 2).

Remove any bolts that attach the drive shaft coupler to the gear box (Photo 3). The coupler is a short pipe that connects between two parts of your tractor’s power train, allowing power to travel through it. Once you’ve removed all of these bolts, pull off the drive shaft coupler completely.

Unbolt the main bearings from inside of your tractor’s frame (Photo 4). These bearings can be found on either side of your tractor’s frame, so you will have to remove them from both sides.

komatsu excavator hydraulic pump-Disconnect the drive shaft to the pump.

Disconnect the drive shaft to the pump. Remove the nuts that hold the pump to the engine block. You may need to use a wrench on these nuts, so be prepared for that.

Disconnect the water pump bolts and remove them. There will be at least two of these bolts, but possibly more if it’s an older vehicle. Use a ratchet or socket wrench to remove these bolts.

Remove the water pump from the vehicle. You will want to get some help with this step because they can be very heavy and difficult to maneuver around in a cramped engine bay.

komatsu excavator hydraulic pump-Remove the mounting bolts for the pump.

Remove the mounting bolts for the pump.

Next, you need to remove the mounting bolts, which are responsible for holding the pump in place. You can find these bolts on the front or rear of the pump. In front-wheel drive cars, you can usually find them on the side of the engine that’s facing away from the front of your car. Use your ratchet and socket to loosen and remove them.

You may need to use a breaker bar and socket to loosen stubborn bolts. If so, insert the end of your breaker bar into one of the sockets and hold it in place with your wrench. Then, apply force with your body weight until it loosens up.

In some cars, you may need to disconnect a bracket or metal rod in order to remove the pump completely. If so, use a ratchet and socket or box wrench to loosen these components before removing them.

You can also try using an impact wrench, which will automatically loosen any stubborn bolts for you with just 1 push of a button.

komatsu excavator hydraulic pump-Remove the old pump.

There are two basic types of pumps: submersible and external. Submersible pumps are installed inside the well, at the bottom of the casing. External pumps are installed outside the well, attached to the discharge pipe coming out of the well. If your pump is more than five years old, or if it’s making a lot of noise or using a lot of electricity, it’s probably time for a new one. You can find a replacement pump at any plumbing supply store or home center, or you can call an irrigation or water-well contractor to have one installed.

komatsu excavator hydraulic pump-Install new pump.

On the side of the pump you will see a small brass fitting with a black rubber hose leading to the engine. This is the oil supply.

Remove this hose, and connect it to the oil supply nipple on your pump. You may need an adapter if your pump did not come with one.

Use teflon tape, thread sealer tape or high vacuum grease to seal any threaded connections.

Connect one end of your clear hose to the pump intake (usually on top) and run it up through the floor where you can see it easily.

When you start the engine for the first time, watch for bubbles in this line. If you see them, shut off the engine immediately as your pump is sucking air instead of oil and is about to be damaged.

komatsu excavator hydraulic pump-You can replace a Komatsu excavator hydraulic pump if you follow these steps.

Komatsu hydraulic pumps are designed to last a long time. However, if you work in a harsh environment or put your machine under constant stress, you might have to replace it. You can do this yourself if you have the right tools and follow the procedure carefully.

Remove the cover on top of the pump to expose the drive shaft. Loosen the nut that holds the pulley in place and remove it from the drive shaft. Remove the bolts that hold the fan in place so that it can be removed. Remove all bolts holding the pump in place and slide it out of its housing. Make sure all hoses are disconnected before doing so.

Slide your new pump into position and ensure that none of its hoses are pinched or twisted. Replace all bolts and tighten them securely using a torque wrench. Check to make sure everything lines up perfectly with the housing, then reattach all hoses and tighten them securely as well. Reattach the fan then slide the pulley over the shaft, tightening its bolt once again with a torque wrench. Replace the cover then check for leaks around all connections before starting your machine back up again.