komatsu siwng problem pc50uu-2 and solution

I want to share some information with you regarding komatsu siwng problem pc50uu-2 and solution because I think it will be the key to helping you get on the fast track towards your success.

Check the pc50uu-2 hydraulic oil level in the oil tank

Check the pc50uu-2 hydraulic oil level in the oil tank regularly, and add oil if necessary. When adding oil, add new hydraulic oil of the specified grade gradually through the filler hole.

When adding oil, remove debris first, clean the area around the filler hole with a clean rag and then fill it with new hydraulic oil.

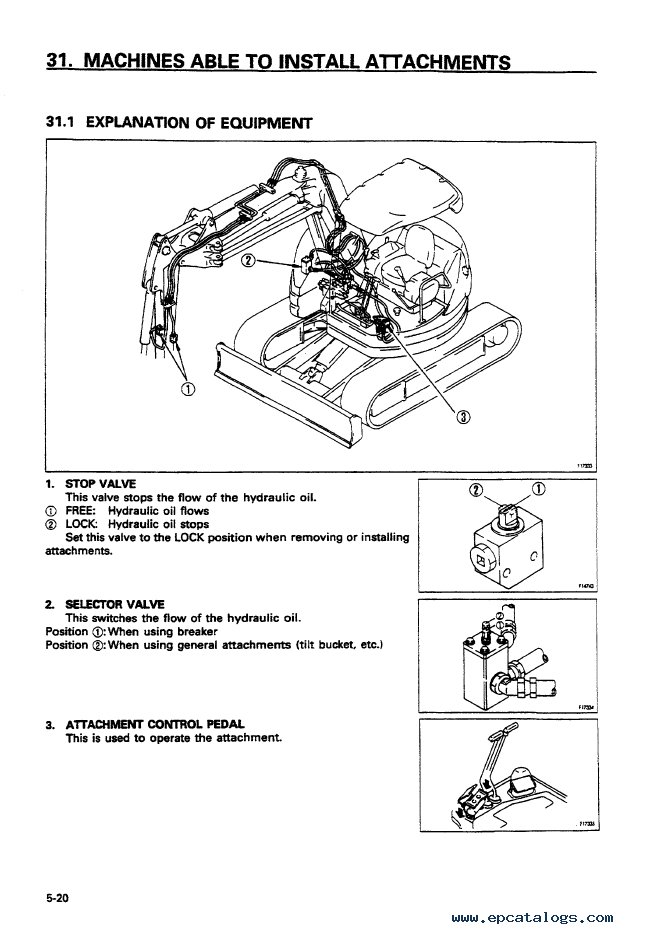

The hydraulic system of this excavator is equipped with a circuit breaker to protect the hydraulic components from overheating and damage caused by abnormal conditions such as lack of lubricating oil or excessive pressure in each part of the circuit.

If an abnormal condition occurs, the circuit breaker will constantly pop up on the handle until it is reset, and at this time all hydraulic functions are disabled.

Check pc50uu-2 whether the hydraulic oil circuit is normal. If there is a fault, repair and repair it

If the above operation is correct, check whether the hydraulic pump of pc50uu-2 works normally. The relevant method is as follows:

1. Remove the oil filter to see if there is any metal powder in the filter element

2. Check whether the rotation direction of the pump rotor is consistent with that required by the system

3. Whether there is metal powder in the suction pipe or suction port of the oil pump, and whether foreign matter jamming causes deformation or damage to the suction pipe;

4. Check whether there are scratches, scratches or cracks in the rotor of PC50UU-2 hydraulic pump;

Check pc50uu-2 whether the pilot valve capacity of the main control valve is small. If it is small, remove the pilot valve or make up pressure

1. Check pc50uu-2 whether the pilot valve capacity of the main control valve is small. If it is small, remove the pilot valve or make up pressure;

2. Check the pilot oil circuit and whether there is a blockage in the hole of the main control valve;

3. The main control valve is stuck or has a large leakage;

4. The distance between the plunger and the valve seat of the main control valve is too large, or the spring force is too small, which causes the plunger to fall off;

5. The ratio of pilot oil pressure to working oil pressure is too low, and it is not sensitive enough to require adjustment;

6. The pressure relief valves are not adjusted well, causing excessive flow resistance in the system, thereby reducing sensitivity;

7. The automatic return valve does not work well and does not return quickly, so that it cannot follow up when going down and cause sluggishness;

8. If a hydraulic hammer (piston type) with a high-pressure accumulator is installed on one end of the boom cylinder and its cross-section area is larger than that of the boom cylinder, it will also cause sluggishness when going down.

Check if there are foreign materials in pc50uu-2 various filters

If it is found that the excavator can not start or the engine exhaust is abnormal, you should check whether there are foreign matters in the fuel filter. If there are impurities, you should immediately clean and replace the filter element. The same method can be used to check whether the hydraulic oil filter element of the hydraulic system has been blocked by foreign matter.

Check if there are foreign objects stuck in the pc50uu-2 control valve spool

Cleaning the PC50UU-2 control valve spool is a very simple method. Only by removing the dust and mud on the surface of the spool can the function of the control valve be fully exerted. So how to clean the PC50UU-2 control valve spool?

In order to ensure the normal use of PC50UU-2 control valves, you must pay attention to regular maintenance and cleaning of PC50UU-2 control valves. The main methods are: check if there are foreign objects stuck in the pilot hole of the spool and clean it; check for leakage at each sealing surface; check that all parts are not loose, missing or damaged; check whether each connecting bolt is fastened.

Check whether the pc50uu-2 plunger pump is worn and replace it if necessary

Engine speed is too low: Check whether the engine speed is too low, adjust the engine speed or replace it with a new one.

Pump suction resistance is too large: check whether the fuel tank is blocked, clean the fuel tank, remove the clogged objects in the oil suction pipe and check whether the oil filter is blocked; check whether the plunger pump has been worn and replace it if necessary.

Fuel injection pressure is lower than normal: check that the plunger pump has been worn and replace it if necessary.

The fuel injection nozzle of a PC50uu-2 excavator is worn and replaced as required: check whether there are impurities in the fuel tank and clean it; check whether there are impurities in the fuel pipe and clean it; check whether there are impurities in the fuel filter; check for wear on the pc50uu-2 plunger pump, etc.

It may be caused by impurities in the oil tank. At this time, remove the inlet filter screen installed on the pipeline to prevent impurities from entering the plunger pump and clean it at any time

1. If a water pipe is installed or used incorrectly, it is easy to cause water droplets or particles to enter the pressure tank and cause freezing. The correct method should be to set up a drain valve before the water pump, so that when an ice blockage occurs, put the pump in reverse through the drain valve, so that it can easily discharge the ice blockage.

2. Before starting each time, check whether there is any abnormality in the power cord of the motor or other parts, such as breaking off or wearing out a part of the wire or casing. If you find any abnormality, you must replace it with a new one before you can use it to avoid accidents.

3. When using a centrifugal water pump, if there is no sediment and debris in the water source, then no filter needs to be installed in front of it; if there is any debris in it, then install a filter at its inlet to prevent debris from entering and damaging its impeller or shaft seal ring .

The filter element of the filter used for filtering hydraulic oil should be cleaned regularly and replaced with a new one when necessary

The filter element of the filter used for filtering hydraulic oil should be cleaned regularly and replaced with a new one when necessary. In addition, the filter should be cleaned at least once a week to prevent the filter from being blocked. If the impurities in the filter are too large, the oil pressure will drop sharply, and even cause a pressure block in extreme cases.

The filter is generally equipped on both sides of the fuel tank. Its installation position can be arranged according to user needs. The filter is equipped with automatic exhaust valve, which will automatically discharge air when it is started and running under high pressure. The core part of the filter is made of steel plate, which has good strength and anti-seismic performance.

komatsu excavator pc50uu-2 is one kind of komatsu new model production. And its main role is to work on excavating sand and soil in building construction, water conservancy and irrigation, roadbed building and opencast production, etc. All the models komatsu products are produced under the precondition of innovation, quality first, safety priority and environmental protection so that to supply the domestic market and aborad market with reliable non-standby products foundation. It can be understood that komatsu products take a place in people’s heart due to their reliable quality, good performance and low operation cost . So you could know komatsu mini excavator pc50uu-2 ‘s information from here.